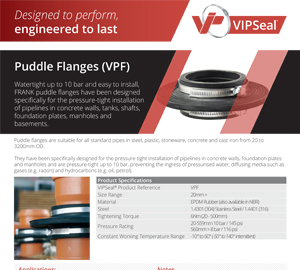

Watertight up to 10 bar and easy to install, FRANK puddle flanges have been designed specifically for the pressure-tight installation of pipelines in concrete walls, tanks, shafts, foundation plates, manholes and basements.

Installed on the external pipe surface to act as a barrier, they diffuse gases and hydrocarbons and are suitable for all standard steel, plastic, clay, concrete and cast iron pipes from DN20 to DN3200 mm making them a perfect solution for any application.

Puddle flanges applications:

- To prevent water or gas getting into buildings via pipe penetrations

- Domestic and commercial developments

- Suitable for use with all smooth walled pipes provided that the pipe surface, at the point of

installation, is clean, smooth and free of pores or surface imperfections - Most pipe sizes can be accommodated from 20mm through to 3200mm diameter

- Installed on pipes during construction where water penetration has to be prevented

Applications:

- To prevent water or gas getting into buildings via pipe penetrations.

- Domestic and commercial developments.

- Suitable for use with all smooth walled pipes provided that the pipe surface, at the point of installation, is clean, smooth and free of pores or surface imperfections.

- Most pipe sizes can be accommodated from 20mm through to 3200mm diameter.

- Installed on pipes during construction where water penetration has to be prevented.

Notes:

- Puddle flanges are supplied with the ID smaller than the host pipe OD and are stretched over during installation.

- Concrete coverage should be at least 50mm against each surface of the puddle flange using waterproof concrete.

- Depending on the size, puddle flanges have an OD 75-100mm larger than the host pipe OD.

- The pipe must be fully supported to withstand the concrete pouring process as puddle flanges do not provide any axial restraint.

Benefits:

- Tested up to 10 bar water pressure.

- Easy to install and a cost effective solution.

- Can be installed in walls, floors and ceilings

- Good general chemical resistance.

Materials

FRANK puddle flanges are manufactured in EPDM and NBR. EPDM is chemically resistant to a wide range of substances and offers outstanding weather and ozone resistance. For applications in connection with oil and petrol, FRANK puddle flanges made in NBR are the preferred option.

- 20-354mm

- 10 bar pressure rating

- supplied with 2 x SS tension bands

- 355-559mm

- 10 bar pressure rating

- Supplied with 3 x SS tension bands

- 360mm>

- 8 bar pressure rating

- Clamping band and 3 x SS clamps and tool supplied separately

| VIPSeal Ref No. | Pipe OD From | Pipe OD To |

|---|---|---|

| VPF20 | 18 | 24 |

| VPF25 | 23 | 29 |

| VPF32 | 31 | 37 |

| VPF40 | 40 | 46 |

| VPF50 | 50 | 56 |

| VPF63 | 62 | 69 |

| VPF75 | 73 | 82 |

| VPF90 | 86 | 97 |

| VPF100 | 98 | 109 |

| VPF110 | 108 | 121 |

| VPF125 | 123 | 136 |

| VPF145 | 136 | 155 |

| VPF160 | 158 | 177 |

| VPF180 | 177 | 197 |

| VPF200 | 199 | 224 |

| VPF225 | 220 | 249 |

| VPF250 | 250 | 279 |

| VPF280 | 280 | 314 |

| VPF315 | 315 | 354 |

| VIPSeal Ref No. | Pipe OD From | Pipe OD To |

|---|---|---|

| VPF355 | 355 | 399 |

| VPF400 | 400 | 449 |

| VPF450 | 450 | 499 |

| VPF500 | 500 | 559 |

| VIPSeal Ref No. | Pipe OD From | Pipe OD To |

|---|---|---|

| VPF560 | 560 | 629 |

| VPF630 | 630 | 709 |

| VPF710 | 710 | 799 |

| VPF800 | 800 | 899 |

| VPF900 | 900 | 999 |

| VPF1000 | 1000 | 1150 |

| VPF1200 | 1200 | 1350 |

| VPF1400 | 1400 | 1550 |

| VPF1600 | 1600 | 1750 |

| VPF1800 | 1800 | 1990 |

Accessories

| VIPSeal Reference | Details |

|---|---|

| VPF SS Band | 30mt Coil |

| VPF SS Clamps | 3 x Flange |

| VPF Clamping Tool |

Larger sizes available on request

Installation

Thanks to the easy-lock tension bands, installing a FRANK puddle flange takes only a few minutes. The puddle flange is mounted by hand on the pipe and secured with the supplied tension bands. A screwdriver or 6mm nut driver can be used to install the tension band on pipes of up to 315 mm in diameter.

For larger pipes, use a clamping tool. Our puddle flange installation kits (DN20 to DN315 mm) now come with an easy-Lock function that allows for even faster installation on the pipe.

- Tested up to 10 bar water pressure

- Easy to install, cost effective solution

- Can be installed in walls, floors and ceilings

- Good chemical resistance

Installation Video up to 315mm

Installation Video from 355mm